The Home Stretch of Construction

This summer was particularly hot and busy at work so construction time was limited to small chunks here and there. But as fall approached I was able to give some focused time to the train and have been making good progress. A while ago I completed the initial sections so that I could run the trains a little. But trips were limited. The track didn't extend much beyond either switch and someone had to be at the controls all the time. Run time was about 20 seconds before the train had to stop and reverse. The train had to be short with only one or two cars besides the engine.

That gave me plenty of incentive to complete more segments. I was able to add another segment in the back part that runs through the shrubs. And then in just a couple of days I was able to build the ladder railbed for four segments of the layout and was ready to install them in place. Due to the trouble we had getting pieces to line up (future post that's coming) my wife and I laid out the rest of the track, propped up on paver blocks, to make sure the two ends actually connected. I would then disconnect one segment of track, build the railbed, attach the track, set it back in place on the pavers, and make sure everything continued to line up. This went on as each segment of railbed was built. Once there were several consecutive segments ready, we would come back and install it in the ground.

One Sunday everything was ready to go and I was able to focus and install four major segments. I had the process down pretty good so things went smoothly. That is, only a handful of treks back to the garage for tools I forgot to bring out. This day, since I was extending existing track, I could load up a work train and deliver tools right where I needed them. The installation was the most rugged part of the layout with the jungle closing in on both sides and some dense roots slowing down the installation.

The basic process began with disconnecting the track. Here the dump truck was invaluable so pieces didn't get lost to the wilderness. Once the track was loose, it would be carted away leaving the ladder railbed in the desired location. I used an auger to drill holes where the support posts would go. The railbed would be removed and I would pound the bottom parts of the posts into the ground. They were checked for plumb during this time. Then smaller posts with a tee on top were dropped in (not shown in the video). The railbed was then replaced. If the rail gods were happy that day, the railbed aligned with the posts. If not, I returned back to the start of the process. Then screws were put through the railbed and tees to hold it in place. Finally, the whole track was leveled.

It all went pretty quick, didn't it 😀

Building the railbed for this part was quite simple as it is just straight. As long as I kept everything square it would work out. I got squarish. I don't think I pay the engineer enough to expect better than that.

I got the locals (scale) to help and this last segment went in quickly. Easy access and everything dropped into place. With these final pieces in place and leveled, there was a complete loop! No more quick back and forth trips.

I had a couple of bumpers to keep the train from running off the track as they were extended. The bumpers actually did their job a couple of times when I hit the throttle instead of the brake. As I would add new segments and install them into the ground, the bumper would move along giving a little extra room for the train. Now it was time to inaugurate the last segment of track.

And with that, Phase 1 of the Coastal Titans Railroad was complete. We just need to wait for final inspection and operational approval and we'll be ready for passengers.

|

| Completed back segment |

One Sunday everything was ready to go and I was able to focus and install four major segments. I had the process down pretty good so things went smoothly. That is, only a handful of treks back to the garage for tools I forgot to bring out. This day, since I was extending existing track, I could load up a work train and deliver tools right where I needed them. The installation was the most rugged part of the layout with the jungle closing in on both sides and some dense roots slowing down the installation.

The basic process began with disconnecting the track. Here the dump truck was invaluable so pieces didn't get lost to the wilderness. Once the track was loose, it would be carted away leaving the ladder railbed in the desired location. I used an auger to drill holes where the support posts would go. The railbed would be removed and I would pound the bottom parts of the posts into the ground. They were checked for plumb during this time. Then smaller posts with a tee on top were dropped in (not shown in the video). The railbed was then replaced. If the rail gods were happy that day, the railbed aligned with the posts. If not, I returned back to the start of the process. Then screws were put through the railbed and tees to hold it in place. Finally, the whole track was leveled.

It all went pretty quick, didn't it 😀

|

| Final bits of track ready to install |

After that hard section was finished, and I had lunch, there was only an extended straight leg, the side along the lawn, to build. That would be easy. I had received some free straight track from a club member several months earlier. It gave me something to play with without feeling like I was blowing good money (Track is a bit expensive. But free track is free!). I also wasn't sure how good my design (seemed OK) and install (plenty of problems) would be so I left this last section to float a little bit. Yet, I ended up not needing the slack. It matched within an inch or so of the design specification. I laid out the track, measured, and made a few cuts. I am also thinking of a possible siding or diversion along this stretch so I put in a couple of pieces that would be easy to swap out for switches in the future.

Building the railbed for this part was quite simple as it is just straight. As long as I kept everything square it would work out. I got squarish. I don't think I pay the engineer enough to expect better than that.

I got the locals (scale) to help and this last segment went in quickly. Easy access and everything dropped into place. With these final pieces in place and leveled, there was a complete loop! No more quick back and forth trips.

|

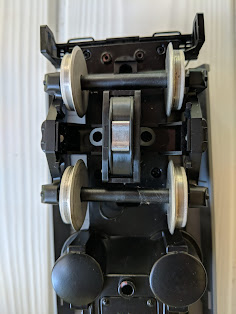

| Bumper protecting the last segment to be installed |

I had a couple of bumpers to keep the train from running off the track as they were extended. The bumpers actually did their job a couple of times when I hit the throttle instead of the brake. As I would add new segments and install them into the ground, the bumper would move along giving a little extra room for the train. Now it was time to inaugurate the last segment of track.

And with that, Phase 1 of the Coastal Titans Railroad was complete. We just need to wait for final inspection and operational approval and we'll be ready for passengers.

Comments

Post a Comment