Success with the Ladder Railbed

Previously I've talked about some of the challenges I faced once I settled on using a raised ladder railbed. I had to try several different approaches until I came up with a method that consistently gave me the desired curvature. This again came for a hint I got from Ron at O Scale Trains By Ron. Instead of trying to form the railbed and then attach the track to it, I would use the track to help form the shape. For someone trained as a theoretician, this was far from my wheelhouse. But as someone who wanted to run trains in the yard, it was a godsend. Finally, I was making progress with the railbed. It still took some time for me to get the technique down and there were times when it still didn't quite work out but I was definitely approaching success (asymptotically for those with a math bend).

The idea is straightforward. Start with attaching a spacer to one of the girders several inches in from the end. The spacer should be aligned with one of the ties on the track, preferably one that already had a screw hole in it, and the girder should extend just beyond the close end of the track. This is so there is room to trim off the end of the girder when installing. For a tight curve, I go 6-8" along to place the next spacer. For a shallower curve, I go more like 8-10". Again, good if it is at a tie with a hole. If there isn't, then I just drill a small screw hole in the tie. It was sometimes easier to attach the spacer to the tie and then to the girder. This made sure the along-rail spacing of the spacers was correct.

Next attach the girder on the other side with clamps. To help hold the shape I then move along the remaining rail sticking spacers in and clamping them between the girders. But I don't screw the spacer to anything. Just hold the shape with clamps. Now attach the first spacer to the second girder.

Then put in the third spacer at a tie. Screw to the first girder and clamp if necessary. Then go back and attach the second girder to the second spacer adjusting to make sure the curve of the two girders match the track as close as possible. No matter how hard I tried, it always ended up a little shallower than I wanted so I started trying to over-compensate. I also allowed the trim boards to have a bit of a bend in them when I stored them. That helped encourage the curve a little.

Now keep attaching spacers. Always be one or two ahead on the first girder so you can hold, but adjust the curved girders. I also tried to keep the lengths to about 6 feet. This allowed a little more play when installing if the curve wasn't quite right. There's a gap that can be adjusted and then left or cleaned up with a short connector piece.

Once I had this down I could start building railbeds and preparing to install them. And that's what's coming next.

One problem I encountered with this method was that it depends on the track holding it's shape during the process. A few times I would finish and notice a gap had opened up where two rail pieces. Using a screw-in connector, like Splitjaw, definitely helped here, as well as helping to ensure good contacts once installed.

Until next time...

|

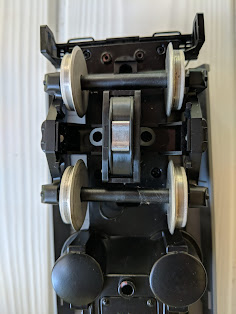

| A set done |

|

| Testing in the garden |

|

| And now ready for painting |

Until next time...

Comments

Post a Comment